Reduce fuel consumption and increase your yield.

Improved efficiency for better results.

When it comes to success, it's all about getting the most out of your machine, especially when things get tough. The top LEXION models offer an impressive fuel efficiency of 1.10 gallons of fuel per acre, and they deliver their maximum performance when you need it most. |

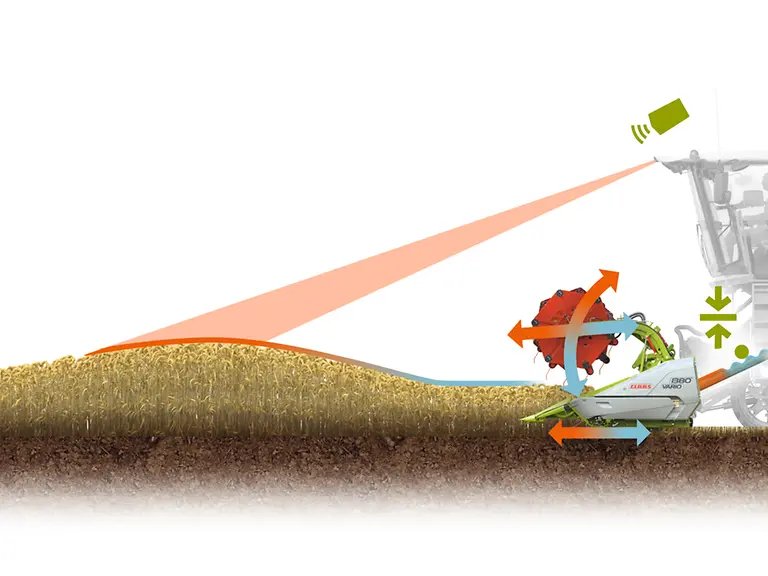

An even crop flow saves fuel. An even crop flow saves fuel.

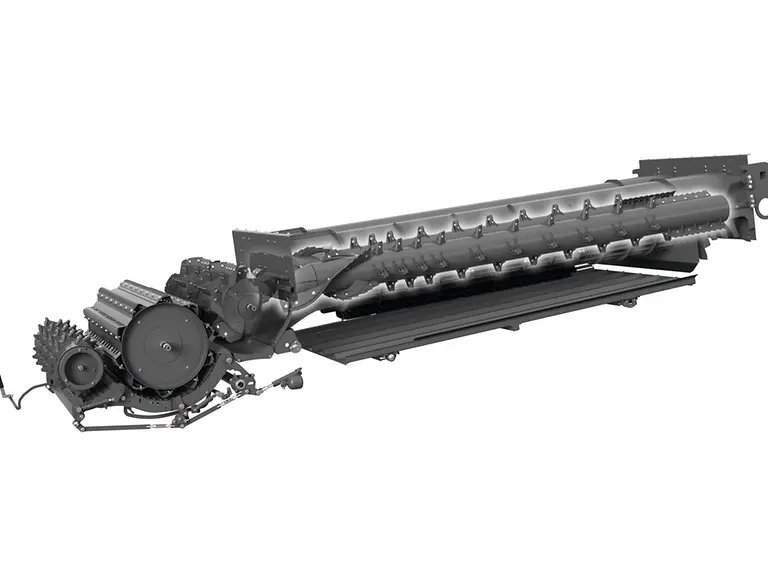

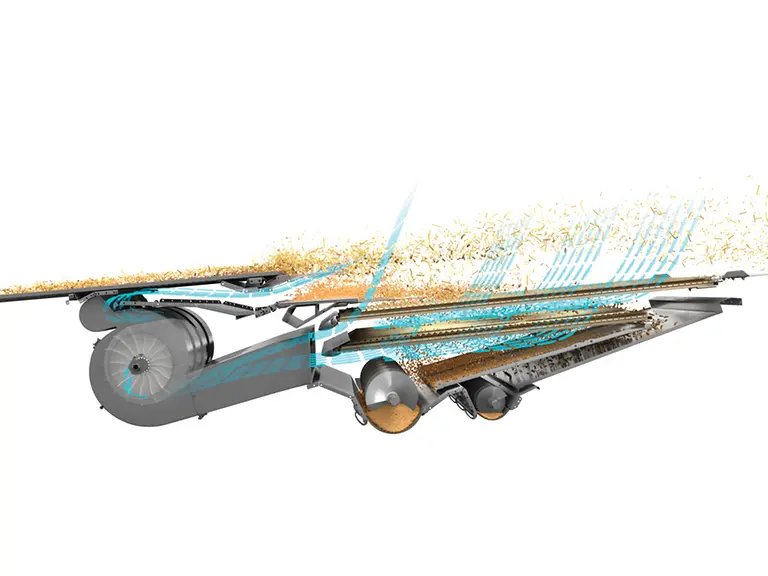

APS SYNFLOW HYBRID.

The APS SYNFLOW HYBRID threshing unit’s 17 11/16 in (450 mm) accelerator drum begins the extremely efficient threshing process, enabling impressive throughput rates.

It accelerates the crop flow evenly at up to 66 ft/s (20 m/s). This generates high centrifugal forces for maximum separation across all concave surfaces.

Large drum diameters and small contact angles enable particularly flat transitions between the threshing and feeder drums as well as the rotors. As a result, the crop flows through the combine in a straight line for maximum efficiency. There are also no unnecessary changes of speed or direction of flow. This protects the straw and saves fuel. |

No compromises.

Harvesting performance needs power.

You can customize the LEXION just how you want it to meet your individual needs and maximize your harvest. -

With 790 hp, the LEXION 8900 is the top model in the series. -

The LEXION 8800 can now call on 700 hp instead of 653 hp while the LEXION 8700 has an output of 626 hp instead of 585. -

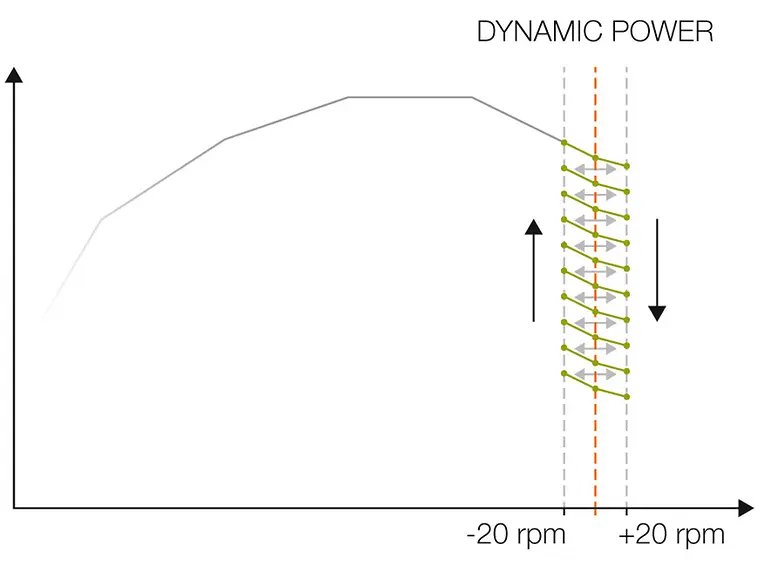

DYNAMIC POWER adjusts the engine output to the amount of power required. This saves you up to 10% of your fuel. -

DYNAMIC COOLING reduces your diesel costs. The variable fan drive automatically adjusts its speed to the amount of cooling needed. -

TERRA TRAC reduces soil compaction. The track units offer maximum driving comfort and are narrow enough for the road. |

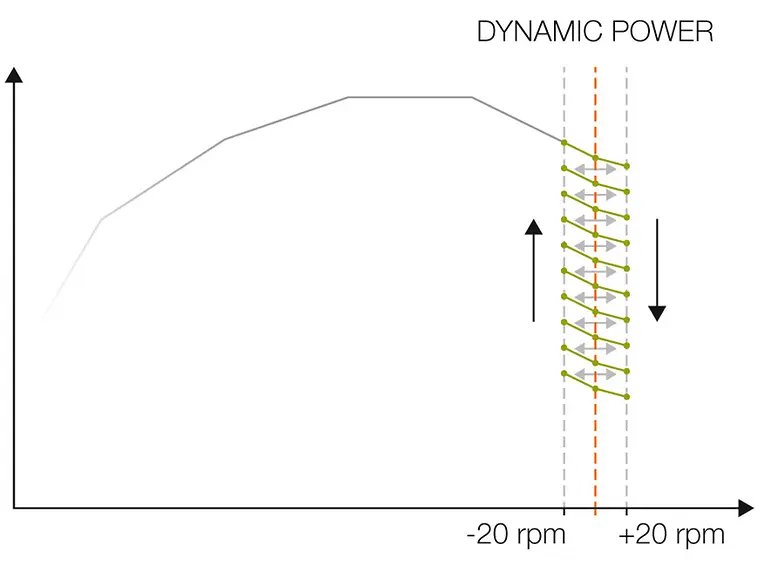

DYNAMIC POWER - the intelligent way to effectively utilize your machine’s hp.

A smarter engine.

DYNAMIC POWER automatically adjusts the engine output of your LEXION to the operating conditions. This means you’re always running with the most efficient power curve when operating under partial load and can save up to 10% of fuel during swathing, for example. When working under maximum load, such as emptying the grain tank with the straw chopper on, maximum engine output is automatically maintained.

DYNAMIC POWER uses a variety of power curves depending on the engine load. For example, if the engine speed changes, the power is automatically adjusted accordingly |

DYNAMIC COOLING - intelligent cooling.

What makes DYNAMIC COOLING so unique? -

Variable fan drive provides cooling when required -

Provides effective and reliable cooling -

Uses full fan speed only under full load -

Minimizes dust clouds -

Keeps the radiator and engine compartment cleaner -

Automatically increases speed to blow dust away from the engine compartment when the grain tank unloading tube is extended -

Extends the air filter maintenance intervals |

25 mph (40 km/h) for fast transfers.

Your time is too valuable to waste.

All LEXION models are equipped with a 2-speed hydrostatic drivetrain with convenient gear selection via the buttons on the armrest. The high efficiency of the hydrostatic drive saves power for optimal use by the rest of the machine. Both the wheeled machines and the TERRA TRAC models can travel at up to 25 mph (40 km/h). |

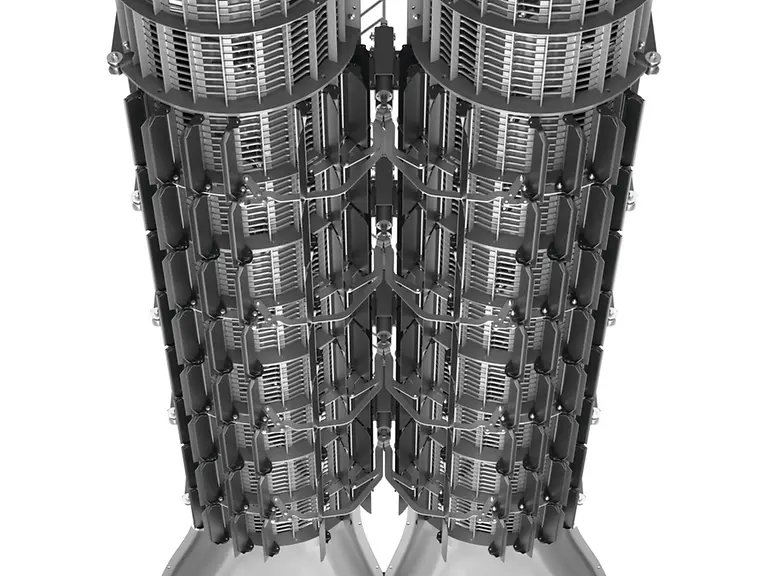

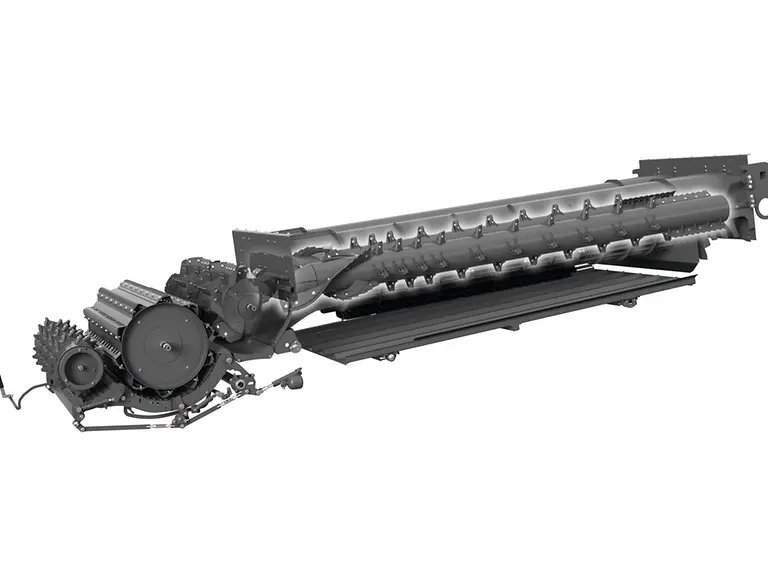

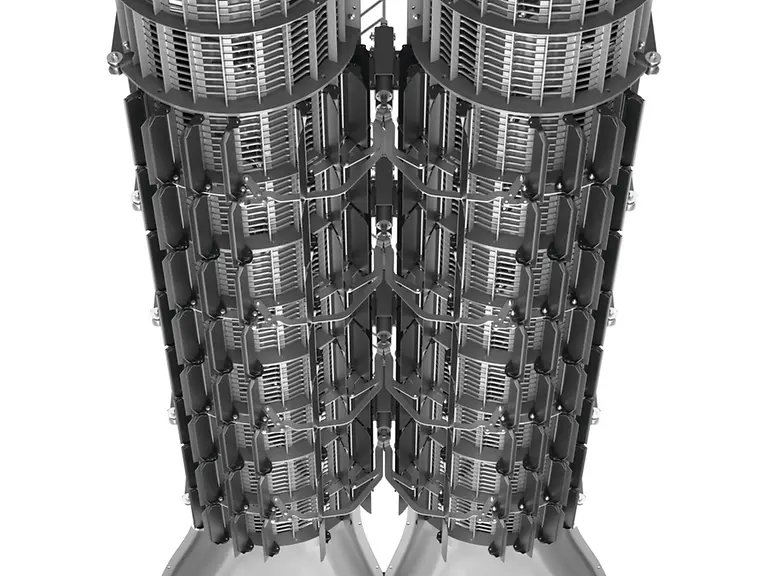

ROTO PLUS gets the most of your crop.

Every grain counts.

The eccentrically positioned ROTO PLUS high-performance rotors generate powerful centrifugal forces to separate any remaining grain from the straw. Each rotor has a diameter of 17 1/2 in (445 mm) and a length of 165 11/32 in (4,200 mm), providing an extra-large separation area.

The mixture of grain, straw and chaff first passes over the grain pan via the separate returns pan before passing over the straw walker steps and on to the cleaning shoe. This significantly reduces the load on the cleaning shoe. |

|

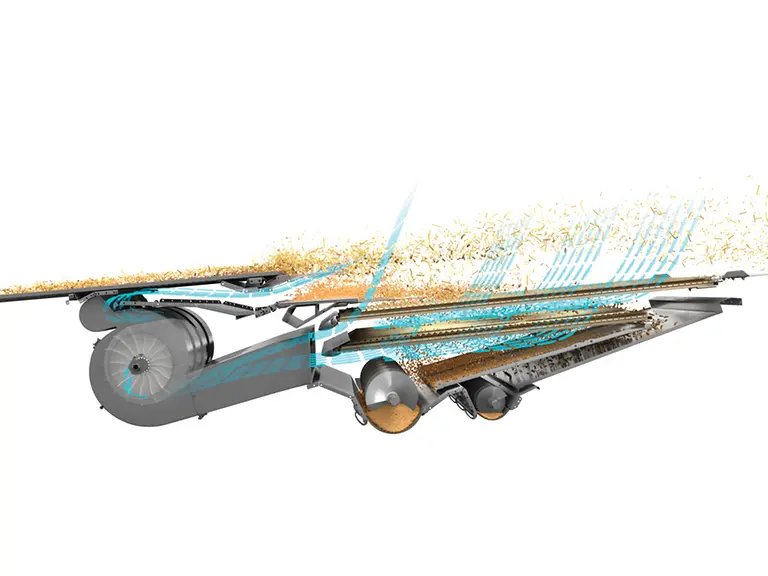

Clean grain is money in your pocket.

Intensive cleaning.

The JET STREAM cleaning system with its hydraulic fan speed variator and high-performance returns is designed specifically to work together with the ROTO PLUS secondary separation unit. A dual-ventilated step enables intensive pre-cleaning.

|

|

Grain tank unloading at up to 48 gps (180 l/s).

Collect your grain quickly and reliably.

With a volume of up to 510 bu (18,000 l), the grain tank has a capacity to match the huge throughput of the LEXION.

At 48 gps (180 l/s) you can unload the large grain tank of the LEXION in record time. If you need to, you can also slow down the flow rate from 48 gps (180 l/s) to 24 gps (90 l/s), immediately stop the unloading process or turn off the augers gradually in order to completely empty the grain tank unloading tube first. − Reliable filling of the transport vehicles − No losses during unloading. |

|

Maximum performance in all crops.

Precision straw spreading.

Even when the machine is operating in strong crosswinds, handling high straw volumes or negotiating side slopes, the power spreader always distributes the straw with precision. Comprising two discharge rotors turning in opposite directions at a constant speed, it takes both the chopped material and the chaff straight from the cleaning section, accelerates it further and spreads it evenly across the entire working width.

During swathing, the chaff blower automatically turns outwards. Swaths of long straw and chaff/broken straw mixture are laid separately. For straw spreading, however, the chaff blower forces the sieve pan discharge straight into the power spreader for active distribution. The chopped straw and the sieve pan discharge are spread across the entire working width. |

|

Precision means profitability.

Take advantage of its smart features.

To increase your yields, you need a combine harvester that can think for you. The LEXION’s self-learning assistance systems, such as CEMOS AUTOMATIC, are working in the background to effectively assist the operator during every minute of the harvesting process. |

|

CEMOS operators are unbeatable.

Optimum performance, even under time pressure.

CEMOS AUTOMATIC is a self-learning operator assistance system that provides continuous, active support throughout the entire harvesting process. Based on the given harvesting specifications, such as grain quality, threshing quality, level of cleaning, straw quality and throughput, the system analyzes sensor feedback and settings during operation and optimizes your LEXION to maximize its performance. |

Build your own CEMOS AUTOMATIC solution. Build your own CEMOS AUTOMATIC solution.

The functions at a glance: -

CEMOS DIALOG guides the operator to the best machine settings -

AUTO CROP FLOW protects the entire system against overload -

AUTO SLOPE controls the fan setting depending on the slope -

CRUISE PILOT actively controls the harvesting speed -

AUTO CLEANING improves cleaning by controlling the sieve opening and fan speed -

AUTO SEPARATION optimizes the rotor speed and rotor flap position to improve the secondary separation -

AUTO THRESHING provides fully automatic adjustment of the threshing concave clearance and the threshing drum speed -

4D cleaning optimizes the rotor flap position depending on the slope in order to make optimum use of the cleaning system -

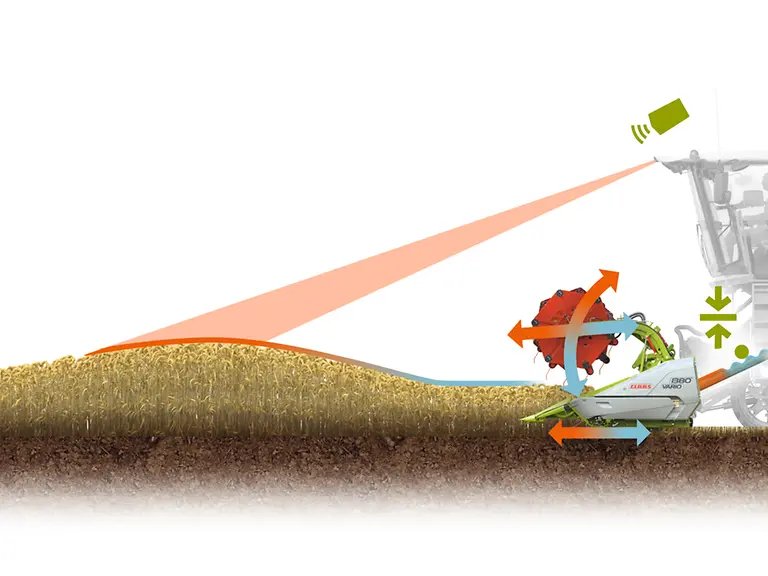

AUTO HEADER actively controls the position of the reel and the VARIO cutterbar table -

AUTO CHOPPING improves the chopped material quality and reduces fuel consumption |

CEMOS DIALOG analyzes the machine’s performance. CEMOS DIALOG analyzes the machine’s performance.

More safety and reliability in the field.

Controlled through CEBIS, the CEMOS DIALOG operator assistance system guides you to the optimal machine setup. After confirming the settings you want, CEMOS DIALOG does the rest. You’re frequently prompted to check the settings, which also gives you more insight into how to choose the right settings for the given conditions.

The machine gives you constant feedback on which settings could be optimized. It lists all the factors imposing the greatest limitations on throughput and actively suggests ways to increase performance.

Harvest with minimal grain losses. -

You only have to calibrate the loss sensors at the start of the day. -

CEMOS DIALOG provides active feedback on loss measurements. -

After adjusting the loss level, the sensitivity of the sensors is corrected automatically. -

The machine always operates right up to the limit set for acceptable losses. |

Keep the number of passes to a minimum. Keep the number of passes to a minimum.

Harvest with pinpoint precision.

Steering systems are an essential tool in your everyday work. The LEXION can be equipped with automatic steering systems, which you can employ depending on the job at hand: the digital AUTO PILOT or the satellite-based GPS PILOT CEMIS 1200. |

Digital solutions gives you a competitive edge. Digital solutions gives you a competitive edge.

A connected LEXION is more productive. -

Machine connect shares machine data via the cloud. -

With CEMIS 1200 you can create and manage all your jobs directly on the machine. -

DataConnect allows you to process your machine data, regardless of manufacturer. -

Machine connect simplifies maintenance and service. -

CEMOS CONNECT links the machines in your fleet and allows you to share settings between them. |

Reliability gives you peace of mind. Reliability gives you peace of mind.

Operating reliability you can count on.

To be the best, it’s not enough for a combine harvester to raise the bar in terms of power and performance, it has to match that with superior durability and reliability. The intelligent drive system of the LEXION is one of the many factors which keep maintenance requirements low and operating reliability high. |

Reliable efficiency. Reliable efficiency.

Unique drive system.

A drive system that has what it takes: -

Hydraulically actuated dry clutch -

Hydraulically tensioned main belts -

Standardized belt tensioners -

Improved power transmission -

Lower maintenance costs |

Less day-to-day maintenance. Less day-to-day maintenance.

Fast maintenance is crucial for your harvest.

When it comes to maintenance, the LEXION continues the legacy of its predecessors as an exceptionally low-maintenance machine. Maintenance intervals are long, with the working hydraulics requiring an oil change only every 1,000 hours. Daily maintenance is quick and easy, and all major service points are easily accessible. |

Optimal accessibility. Optimal accessibility.

More time for harvesting.

The robust engine compartment cover makes it even easier to access the grain tank and to perform any necessary maintenance tasks. It’s slip-resistant and designed to be walked on. Handrails and a folding step provide additional safety. -

All the maintenance points around the machine are easily accessible. -

Contact points for the mobile ladders enable safe access for maintenance and cleaning tasks. -

The side panels, steps and engine compartment are brightly lit. -

A door provides easy access to the grain tank. |

Replace wear parts less often. Replace wear parts less often.

Every minute counts.

All components subject to heavy wear and tear in the crop flow are also available in PREMIUM LINE quality on request. These are the right choice when you have to harvest under extreme conditions which are particularly hard on your combine harvester. PREMIUM LINE components are extra resistant to wear and corrosion and have a very long service life. Even with intensive annual use or when used on difficult-to-harvest crops, these parts will not usually have to be changed until after several harvest seasons. The increased durability is a result of special manufacturing processes, high-quality materials and special coatings. |

Making costs predictable. Making costs predictable.

MAXI CARE PLUS.

MAXI CARE Plus is a combination of service level agreements tailored to your individual requirements for maximum operational reliability and predictable cost management. For example, you can combine MAXI CARE Protect, the extended warranty, with the CLAAS MAXI CARE Maintenance. |

Maintenance contracts increase your operational reliability. Maintenance contracts increase your operational reliability.

MAXI CARE Maintenance.

As part of the MAXI CARE Maintenance contract, all defined maintenance work is carried out by your CLAAS service partner. Of course, only CLAAS ORIGINAL spare parts and operating supplies are used, which gives you full cost transparency and a high resale value. |

Efficiency – increase your productivity

Efficiency – increase your productivity

An even crop flow saves fuel.

An even crop flow saves fuel.

Build your own CEMOS AUTOMATIC solution.

Build your own CEMOS AUTOMATIC solution. CEMOS DIALOG analyzes the machine’s performance.

CEMOS DIALOG analyzes the machine’s performance. Keep the number of passes to a minimum.

Keep the number of passes to a minimum. Digital solutions gives you a competitive edge.

Digital solutions gives you a competitive edge. Reliability gives you peace of mind.

Reliability gives you peace of mind. Reliable efficiency.

Reliable efficiency. Less day-to-day maintenance.

Less day-to-day maintenance. Optimal accessibility.

Optimal accessibility. Replace wear parts less often.

Replace wear parts less often. Making costs predictable.

Making costs predictable. Maintenance contracts increase your operational reliability.

Maintenance contracts increase your operational reliability.