No compromises.

Automation starts at the header.

Harvesting is easier, faster and more convenient when the header is matched perfectly to the crop and the combine harvester. CLAAS headers and CLAAS machines are made for each other. The operators have full access to all operator assistance systems and are able to get maximum results right from the get-go.

|

Maintains a continuous crop flow.

Automatic reel torque control.

The hydraulic reel drive automatically adjusts the reel’s torque to match the harvesting conditions, for example when the crop is lying flat. The automatic height control, which operates based on the specified values for pressure and sensitivity, helps maintain a continuous crop flow and prevents the tines from digging into the soil and causing the reel to come to a stop.

|

AUTOMATIC BELT SPEED for the conveyor belts.

Always the right speed.

The AUTOMATIC BELT SPEED operator assistance system automatically adjusts the speed of the belts to the harvesting speed in all conditions and for every crop.

Advantages for the operator:

-

Continuous, automatic belt speed adjustment, particularly useful for varying crop throughputs

-

Speeds are always set correctly for an even crop flow

|

Automatic front attachment detection saves time.

Ready to harvest.

To get your combine up and running faster, the most important parameters are set automatically. The following information is supplied by the header: cutterbar type, working width, number of sections, reel position, parking position and the AUTO CONTOUR set values for working height and acre counter.

You benefit right from the start.

-

The combine harvester is ready to go in next to no time.

-

It’s significantly easier to operate.

-

The positions of the reel and feeder housing are taken into account to rule out the risk of collisions and damage.

|

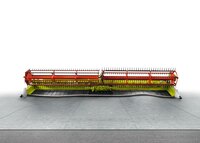

Draper header for more performance.

Powerful headers for all crop types.

Draper headers are ideal for low-growing stalks and crops, and in difficult harvesting conditions (lodged grain, volunteers) which require cutting close the ground. The flexible cutterbar table ensures optimal ground contour following, even with large widths, while the belts make for a gentle and even crop flow.

|

Innovative reel.

For maximum throughput.

The redesigned reel and innovative cam track allow the reel tines to pick up the crop before it is cut, helping to minimize header losses, especially when harvesting lodged grain. The tines ensure that the crop is fed smoothly into the cutterbar, especially when harvesting short crops. In addition, the unique flip-over system prevents the crop from wrapping around the reel. This ensures that the cut crop is fed cleanly, evenly and with little loss to the CONVIO header belts, entering the combine evenly with the crop ear or head first.

|

Cutterbar indicator.

Never miss an important detail.

Knowing the exact position of the cutterbar at any given moment is key to ensuring that it is still optimally following the contours of the ground. Real-time measurements are displayed on a big screen on the right side of the machine, so you’ve got a clear view of what’s going on from the comfort of the cab.

|

|

Plug and play for canola harvesting.

Quick changeovers save time.

Tool-free changeovers from grain crop dividers to side knives is quick and easy. Once the side knives have been mounted, the feed augers are activated automatically and the header is ready for canola harvesting. A hydraulic drive that powers both the side belts

and feed augers ensures synchronous operation for a perfect crop flow.

|

|

Clean cutting in all conditions.

Smooth header guidance.

Hydropneumatically suspended stabilizer wheels prevent the header from rocking when operating over uneven terrain. This feature also ensures smooth header guidance at high driving speeds and offers more driving comfort.

|

|

Powerful work lights.

Well-lit crop flow.

The lighting package provides good all-round visibility when operating in the dark. Work lights on the left and right side walls illuminate the crop edge. The work lights on the left and right on the back panel give you good visibility of the stubble right behind the cutterbar.

Powerful work lights light up both side belts in the cutterbar trough. They make it easy to see the crop moving on the belts in the dark and make any quick adjustments if necessary.

|

CONVIO FLEX and CONVIO.

Powerful drive.

The header’s drivetrain consists of two parts. The mechanical part drives the intake auger and cutterbar while the hydraulic part drives the side belts, the center belt, the reel and the side knives. An overload protection feature protects the entire drivetrain against damage.

|

|

Cutterbar linear drive.

Smooth running.

Depending on the working width, the cutterbar is driven linearly by one or two planetary gear units.

-

One-piece cutterbar with planetary gear unit on the left-hand side of the machine for the 25-ft-3-in (7.7 m) and 30-ft-6-in (9.3 m) models

-

Divided cutterbar, each section with its own planetary gear unit for the 45-ft-3-in (13.8 m), 40-ft-4-in (12.3 m), and 35-ft-5-in (10.8 m) models

-

Both halves run synchronously and in opposite directions

|

|

Powerful reversing.

Prepared for every situation.

Powerful mechanical reversing of the intake auger and the feeder housing is possible when these units are stationary.

-

The side belts and center belt can also be reversed while under full load

-

Slow, gradual starting following reversing

|

CONVIO FLEX

Ideal for low cutting.

Draper headers are ideal for low-growing stalks and crops, and in difficult harvesting conditions (lodged grain, volunteers) which require cutting close the ground. The flexible cutterbar table ensures optimal ground contour following, even with large widths, while the belts make for a gentle and even crop flow.

|

ACTIVE FLOAT for the header.

Optimum assistance for more productivity.

CONVIO FLEX comes with the ACTIVE FLOAT hydropneumatic suspension as standard, which lets you adjust cutterbar’s ground pressure to the field conditions from the comfort of the cab while on the go.

Advantages for the operator:

-

Precision header guidance close to the ground through optimal ground pressure

-

Ideal when working in moist conditions, for example morning or evening dew

|

Less manual work and an optimized cut.

Maximum flexibility for all terrains.

The CONVIO FLEX can be used in four different modes:

1. Grain mode.The cutterbar and cutterbar table are set to a rigid position.

2. Lodged grain mode.The cutterbar is locked in a rigid position but can be changed to flexible mode at the touch of a button while on the go. This is especially useful for avoiding crop losses when dealing with isolated lodged grain during harvesting.

3. Manual flex mode.When manual flex mode is activated, the cutterbar rests on its skids but exerts no ground pressure while following the ground contours. The flexible cutterbar can avoid obstacles with an upward flex of 3 9/16 inches (90 mm) and also follow the ground contours with a downward flex of 5 5/16 inches (135 mm). With a total flex range of 8 7/8 inches (225 mm), CONVIO FLEX is able to adjust to practically all ground conditions.

4. AUTO FLEX mode.AUTO FLEX is a self-learning system that automatically optimizes the height of the header depending on the ground contours, offering decisive advantages:

-

The maximum possible downward flex range is always possible

-

The cutterbar cuts as close as possible to the reel

-

It offers the lowest possible cutting height

|

Side belts, center belt and MULTIFINGER intake auger ensure a smooth crop feed

Side belts, center belt and MULTIFINGER intake auger ensure a smooth crop feed