Basic Basic

- Rotary pump with a capacity of 265 gal/min

- Filling connection 3" through 5-way valve, 2" lines at the suction side

- Pressure sensor for monitoring the spraying pressure and pressure controller to adapt the flow

- Suction and pressure side can be operated manually

- Electronic level indicator at the mixture tank

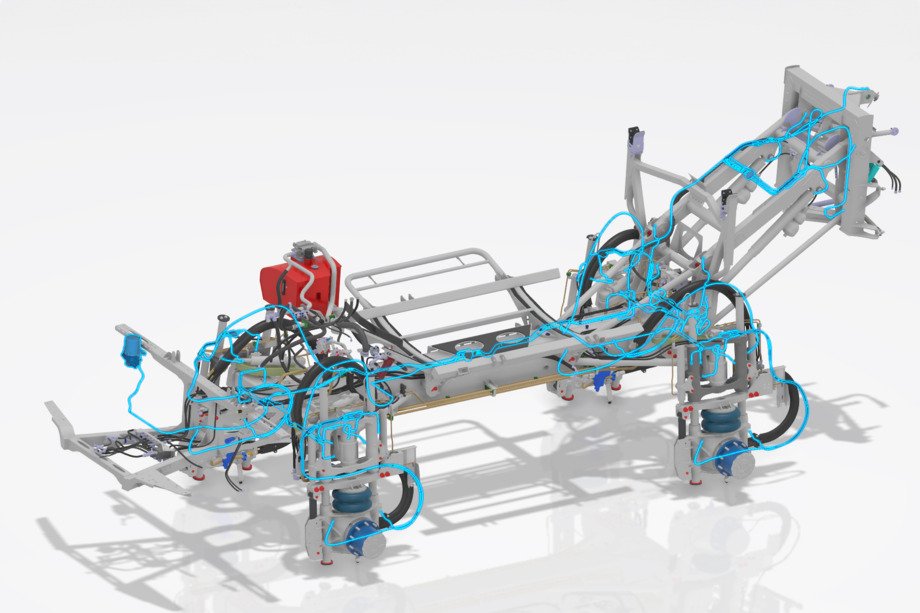

The equipment line Basic the HORSCH Leeb VN and VL are equipped with a 265gal/min rotary pump (filling connection 3" through 5-way valve, 2" lines on the suction side). Suction and pressure side are operated via manual multi-way valves. The spraying pressure is monitored with a pressure sensor and a pressure controller adapts the flow rate. The tank is equipped with an electronic level indicator. A digital level indicator is available as an option in the terminal.

|

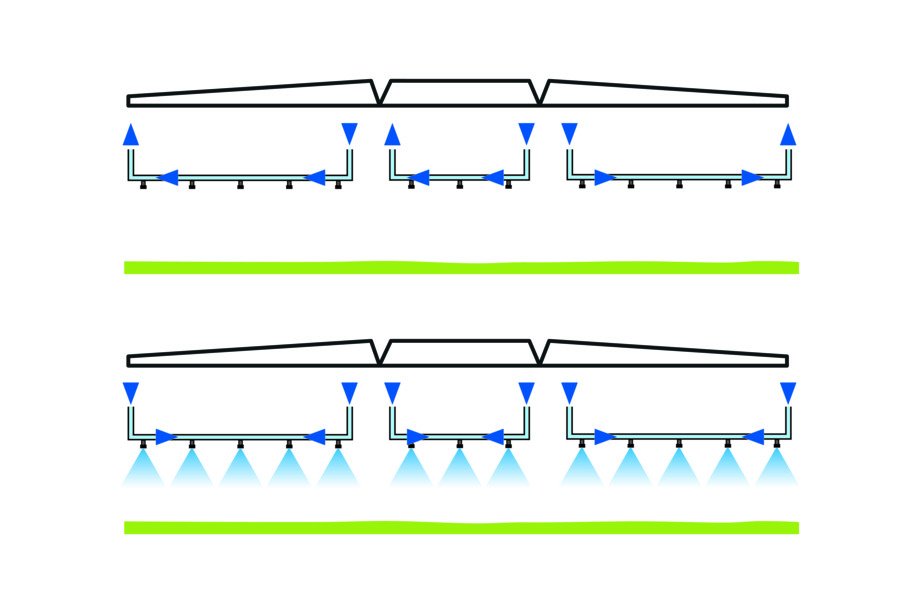

CCS CCS

- Safe and quick cleaning by displacing the mixture from the lines

- Quick cleaning process of the sprayer without having to get off

- Complete control of the cleaning process in the cab

- Electronic level indicator at the mixture tank with automatic switch-off

- Quick and thorough cleaning with optimized water use

The CCS water system guarantees a continuous inside cleaning of tank, lines and boom. The additional CCS piston diaphragm pump for cleaning pumps clean water into the spray lines, the spraying pump removes the residual mixture from nozzles and the spray lines instead of diluting it. This allows the system to be cleaned quickly, thoroughly and with an optimized water consumption – without having to get off the machine directly from the cabin – and the sprayer is completely cleaned when leaving the field. To fill the machine, a powerful rotary pump with Load Sensing is used with manual operation for the suction and pressure side.

|

CCS Pro CCS Pro

- Continuous inside cleaning with several cleaning and rinsing programs, can be operated comfortable in the cab

- Pressure sensors for pump, agitator, inside cleaning and boom, suction and pressure side electrically controlled

- Operation with a large external terminal with all important induction functions

- Quick cleaning process of the sprayer without having to get off

- Relaxed filling process due to the standard automatic two filling limits

- Automatic filling level dependent agitator performance and switch-off

|

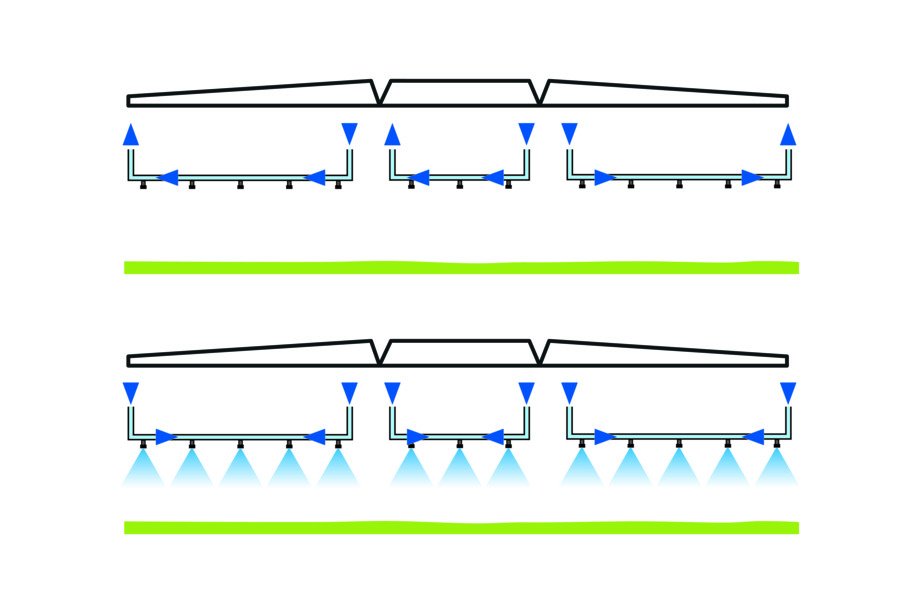

Distribution system and induction hopper Distribution system and induction hopper

- Permanent circulation of the active ingredient solution

- Large pipe and line diameter for optimum circulation, no deposits and blockages

- Permanent liquid at the nozzle, precise switching on and off

- Powerful induction hopper with convincing functions

- Safe cleaning: Displacement of the broth with fresh water

|

PowerGear wheel drive PowerGear wheel drive

- Degree of efficiency in the main working range has been specially optimized for the use in the crop care sector

- Selective traction control for every wheel

- Powerful drive even in steep terrain and at slopes

- Infinitely variable drive from 0 – 35 mph

The PowerGear standard drive allows for optimum performance in the field and on the road. Equipped with standard anti-slip control (ASR) and all-wheel drive, the machine easily manages any terrain. The degree of efficiency that has been optimized for the use in the crop care sector with larger wheel motors at the rear axle and the corresponding higher driving power distributes drive torques in the speed range 0 – 35 mph powerfully and efficiently.

|

HighPowerGear wheel drive HighPowerGear wheel drive

- Can cope with slopes up to 50 %

- Maximum torque at the wheel for highest requirements in the field

- Selective traction control for every wheel

- Degree of efficiency in the main working range has been specially optimized for the use in the crop care sector

- Infinitely variable drive from 0 – 35 mph

For farmers who want to or have to push the limits, we offer the HighPowerGear drive: more driving power when starting, more reserves in wet conditions and more torque in the low speed range for highest requirements in the field. HighPowerGear shows its strength especially with low operational speed and extreme slopes of up to 50 %. When driving slowly below 5 mph or if the machine is on the verge of getting stuck, HighPowerGear provides the required power reserves to manage the most difficult situations.

|

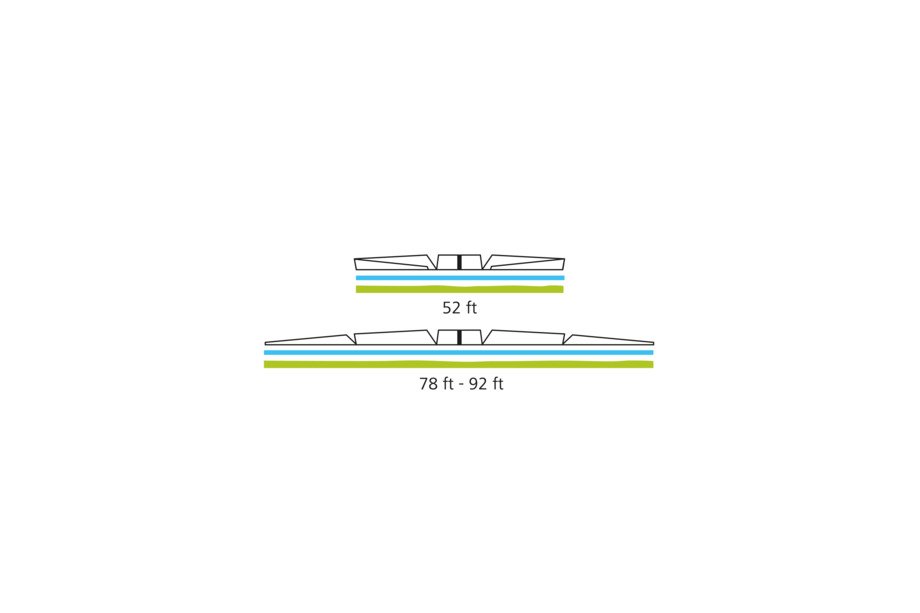

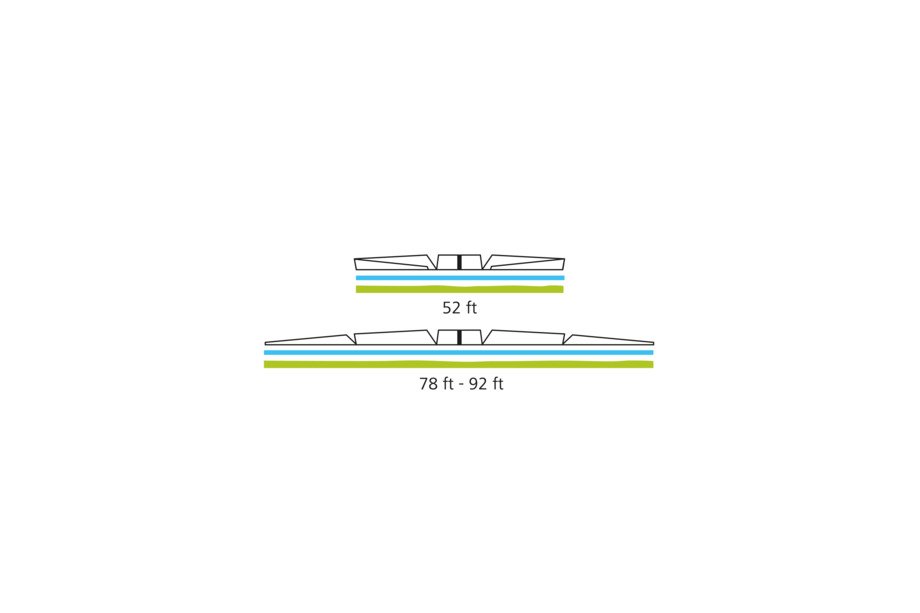

Boom variants Boom variants

- Parallelogram suspension with BoomControl for smooth boom operation in all situations

- Patented suspension with active, pneumatic control of the middle section

- Boom options with working widths from 110' to 160'

- Stable aluminum profile for safe protection of the nozzles, nozzle bodies and spray lines against damage

- Collision protection due to overload protection and damping of the wings

- Overload protection of the outside wings towards the rear, damping of the inside wings to the front and rear

|

MotionControl MotionControl

- Counteracts horizontal movements of the boom wings

- Efficiently smooths horizontal vibrations

- Spring-loaded cylinder bottom of the folding cylinders

MotionControl is used to smooth the horizontal movements in the boom wings. Horizontal vibrations can be smoothed better due to the spring-loaded cylinder bottom of the folding cylinders.

|

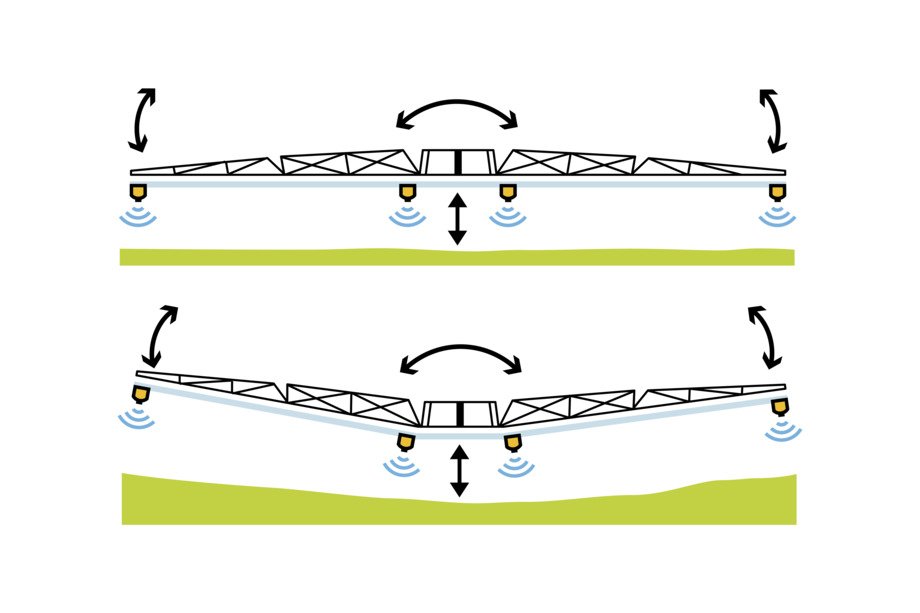

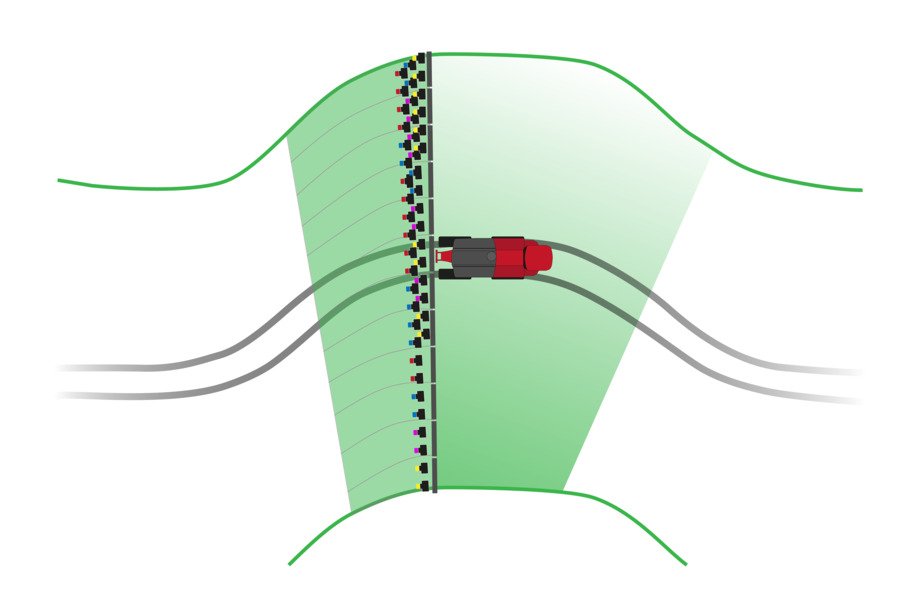

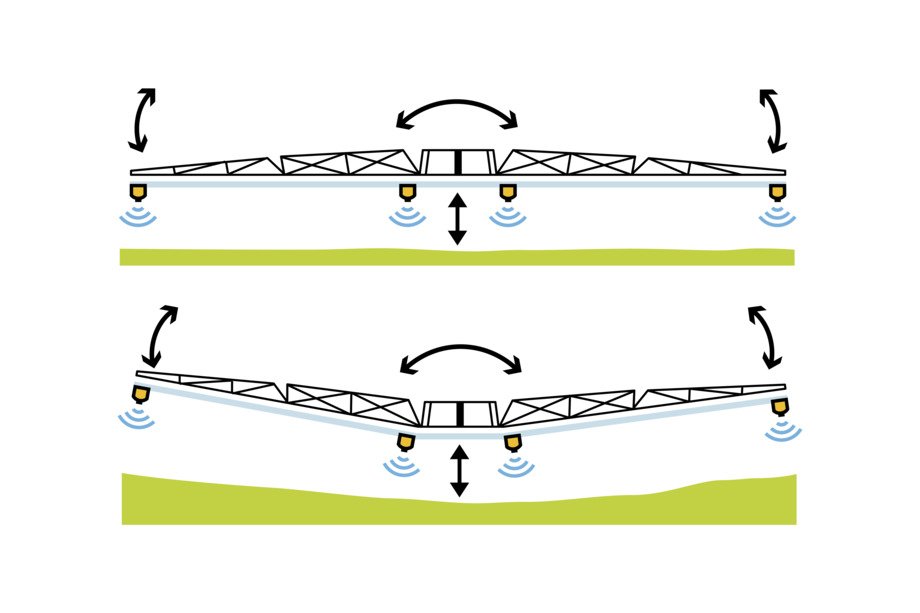

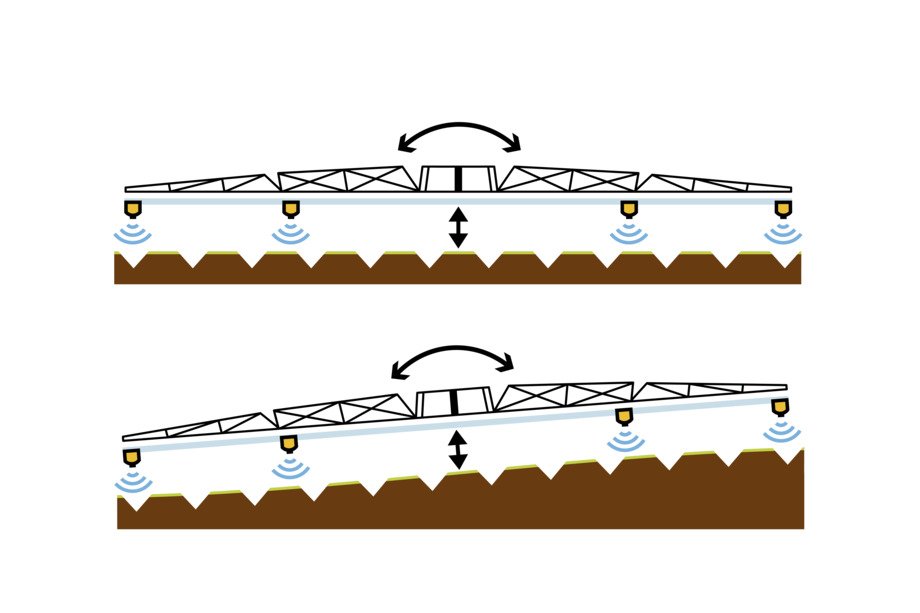

BoomControl Pro BoomControl Pro

- Independent angling of the boom section and the middle section to follow the terrain

- Active adaption of the boom to the terrain due to 4 sensors

- The precise, lowest possible working height is maintained due to automatic boom control system

- Boom control system with a low target height ensures minimum drift

- Boom is completely independent from the machine

With four ultrasonic sensors BoomContro Pro can angle the boom as well as the middle section to better adapt the boom control system to uneven and slightly hilly terrain. Thus, even at high operational speeds, this version of the automatic boom control system can accurately maintain the lowest possible working height. The safe and stable boom control system with a low target height ensures minimum drift. Active adaption of the boom that is completely independent from the machine via the height control of the middle section.

|

BoomControl Pro Plus BoomControl Pro Plus

- Independent angling of the boom section and the middle section to follow the terrain

- Angling (lifting and lowering) of both outside wings

- Due to 6 sensors, the boom actively follows the terrain

- The precise, lowest possible working height is maintained due to automatic boom control system

- Boom control system with a low target height ensures minimum drift

Due to the 6 ultrasonic sensors, BoomControl Pro Plus can angle individual boom wings independently and also angle them at the middle section so that the boom can optimally follow uneven and hilly terrain. Thus, even at maximum operational speed, the top version of the automatic boom control can follow the topography of the field with the lowest possible working height. The safe and stable boom control system with a low target height ensures minimum drift. Active adaption of the boom that is completely independent from the machine via the height control of the middle section.

|

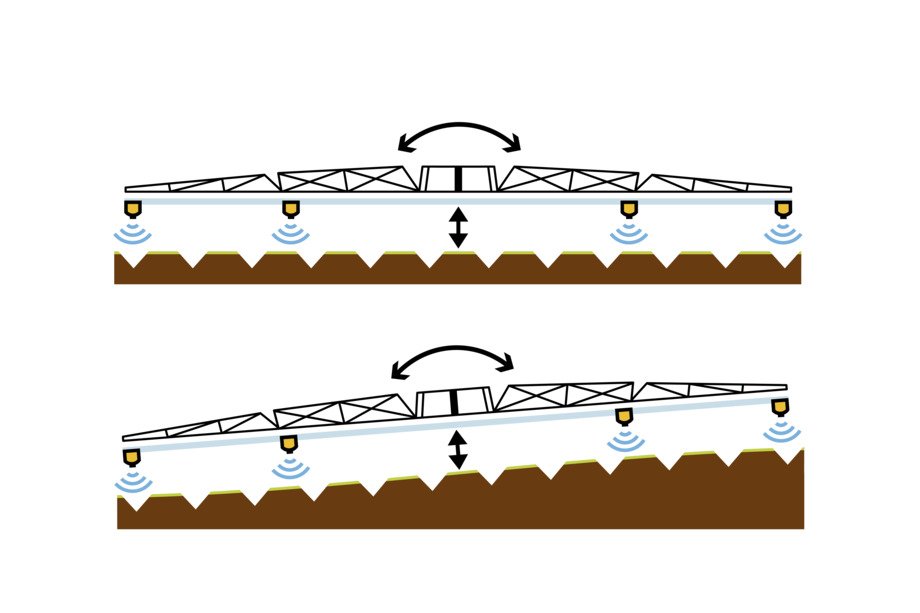

BoomControl/BoomControl Pro extension BoomControl/BoomControl Pro extension

- Due to 2 additional sensors, the boom actively follows the terrain

- To increase the field of vision

- Ideal for ridge and row crops or for reduced working widths

The BoomControl extension completes the basic version with two additional sensors. The sprayer is therefore ideal for the care of ridge and row crops and for reduced working widths of the boom.

|

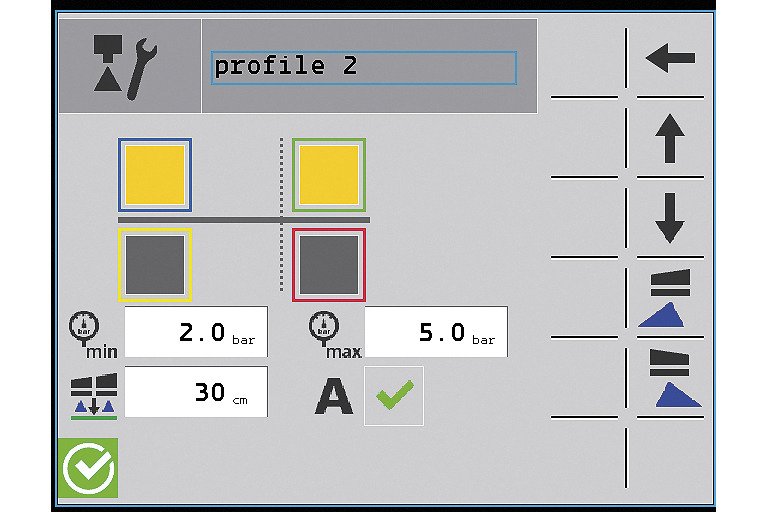

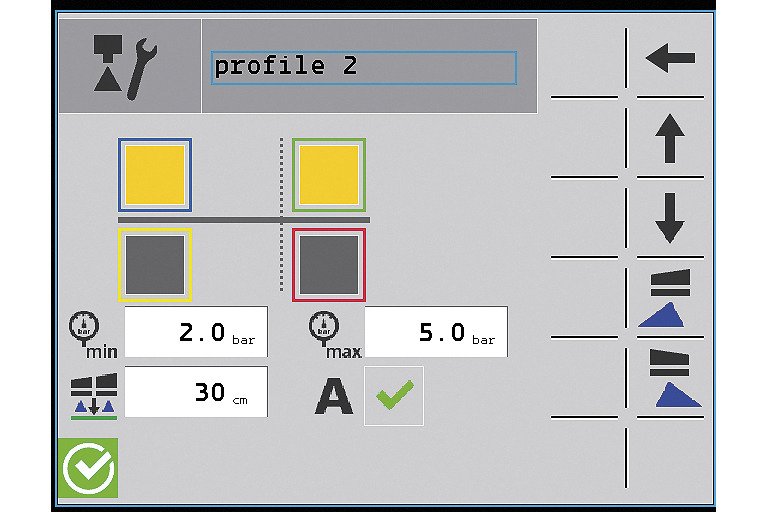

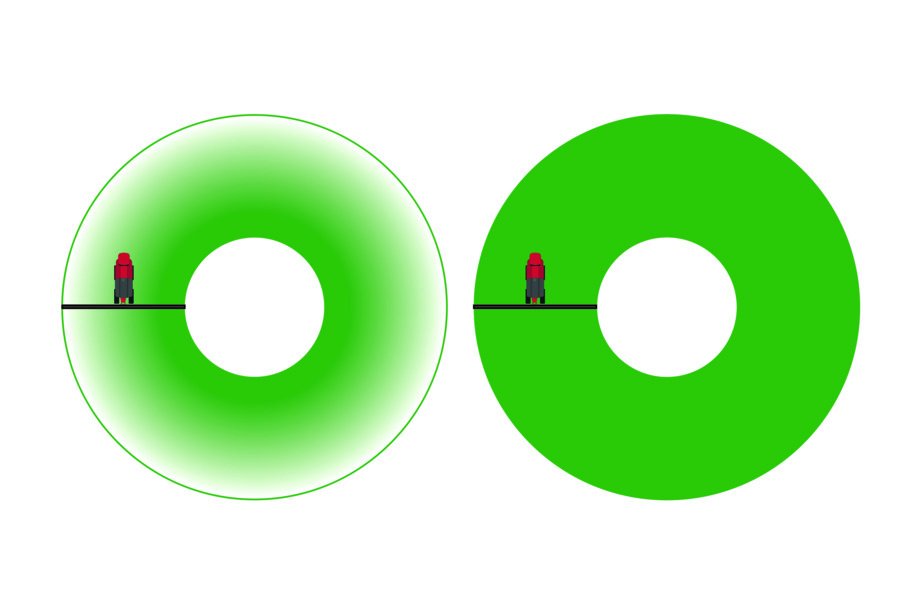

AutoSelect AutoSelect

- Control of the nozzle size in combination with the application rate means the operational speed is adapted

- Possibility to adjust the target height in addition to the pressure range to keep up the distance required

- Optimum distance stipulation control along waters and structures

- Automatic adaption of the boom height depending on the defined nozzle profiles

- Can be switched on or off comfortably in the cabin

|

AutoSelect Pro AutoSelect Pro

- All functions of AutoSelect

- In addition: activation for curve compensation for pneumatic nozzle control

- Rate adjustment when cornering due to combination of the profiles

- Reduction of over and under applying.

AutoSelect Pro takes the HORSCH nozzle control system to the next level. Due to the separate activation of the curve compensation, it is possible to combine profiles and thus increase the application rate on the outside of the curves in a targeted way when cornering. At the same time, the application rate is reduced by switching to a smaller nozzle size on the inside of the curve

|

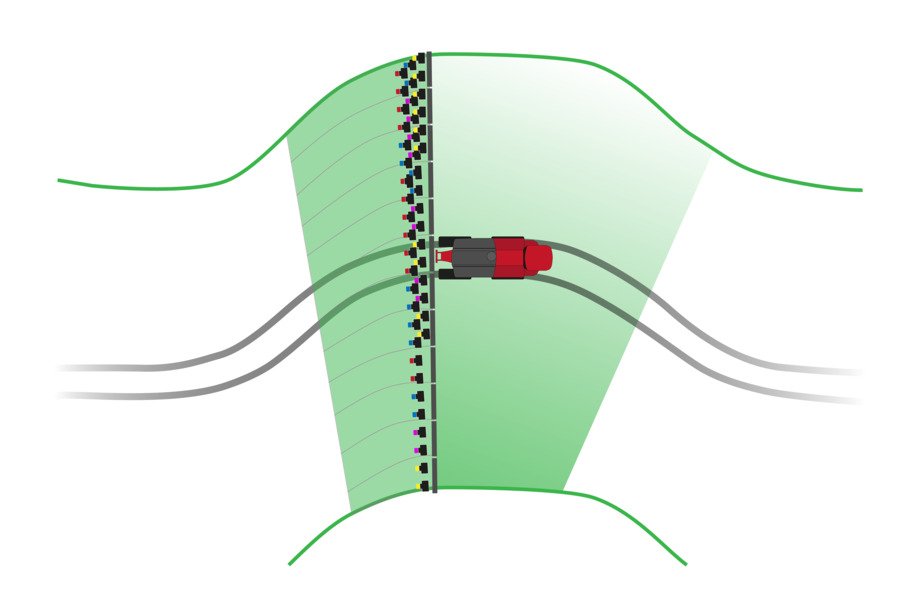

Pneumatic nozzle and section control Pneumatic nozzle and section control

- Individually controlled nozzles, combined pneumatically in sections

- 6 to 42 possible sections (standard sections or individual configuration options)

- Excellent penetration and wetting of the population

- Optimum target area spacing with a nozzle spacing of 10''

- Allows for individual and intelligent application technologies

|

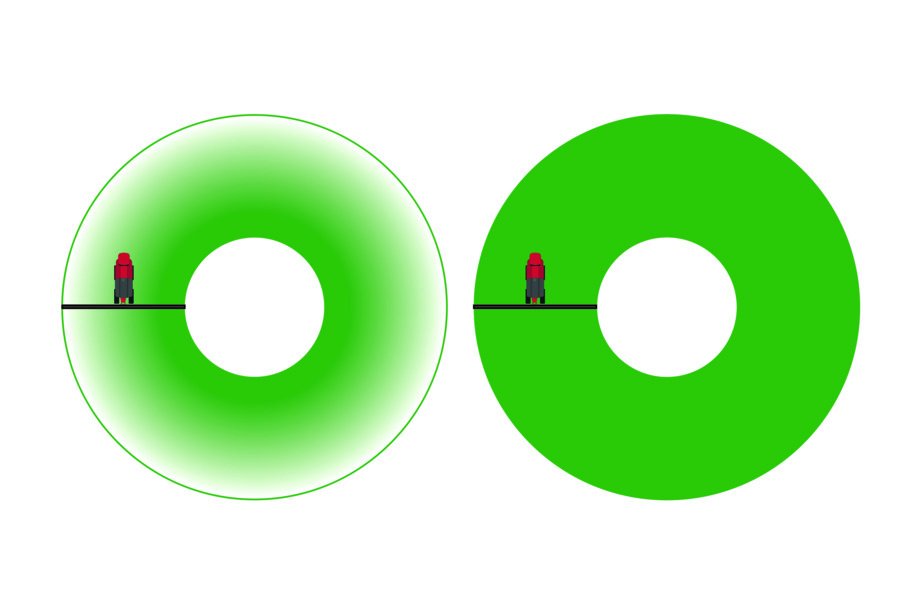

PrecisionSpray PrecisionSpray

- Infinitely variable adaption of the volume flow with constant pressure and drop size

- Constant drop spectrum when using one nozzle

- Lower number of different nozzle sizes required

- Adaption of the application rate without changing the spraying characteristics

- Curve compensation

- Large nozzle bodies that are less prone to clogging

|

Ergonomic operating concept Ergonomic operating concept

- Automatic air conditioning/heating, operation of air conditioning function and lighting integrated in roof rail

- Control lever with multiple assignable buttons integrated in ergonomic control armrest

- 12" display in A-pillar with customizable main page, machine, driving and spraying data

- Armrest with new machine functions, e.g. "Sprayer Ready" - pump start + BoomControl

- Pre-fitting for automatic Cat. IV cab filtering (automatic control, fully integrated into the cab roof and roof rail)

|

Cabin Basic Cabin Basic

- Fabric seat with various adjustment options

- Double cup holder for long working days

- Sunblind's at the front and rear window

The new cab comes with numerous standard features, including a mobile phone holder with induction charging, a footrest, storage compartments, and a cooling compartment. For long days, there’s automatic air-conditioning with heating, and the air-conditioning and lighting controls are in the roof strip. The new control lever has configurable keys and an ergonomic cork handle. The cab roof also includes pre-fitting for the automatic Cat. IV cabin filter system.

The Basic option comes with a fabric seat with adjustable options, a passenger fabric seat, and a double cup holder. Sunblinds are mounted on the front and rear windows.

|

Cabin Pro Cabin Pro

- Swiveling comfort leather seat with seat heating and ventilation

- Triple cup holder for long working days

- Sunblind's at the front, rear and side window

- In addition, there is a floor mat and a terminal attachment bar

|

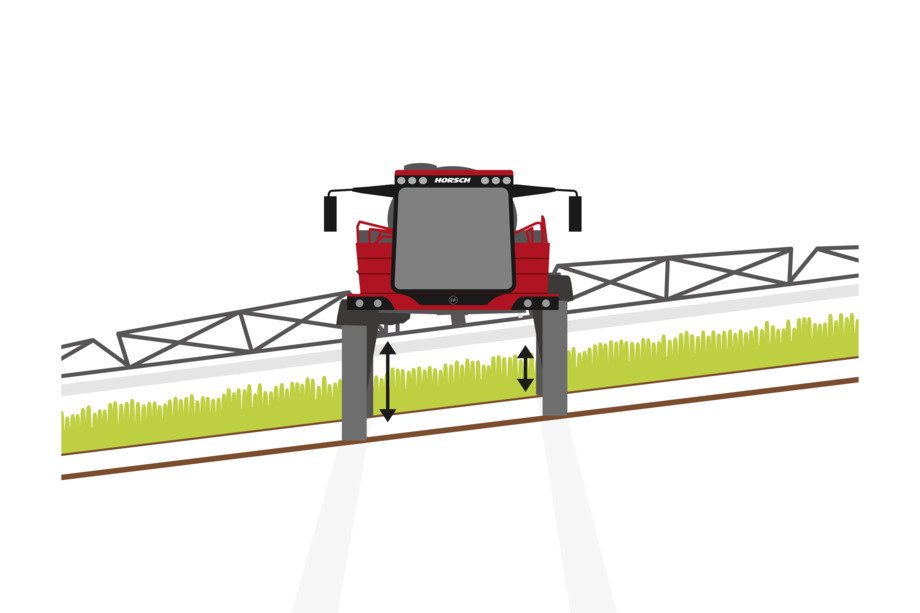

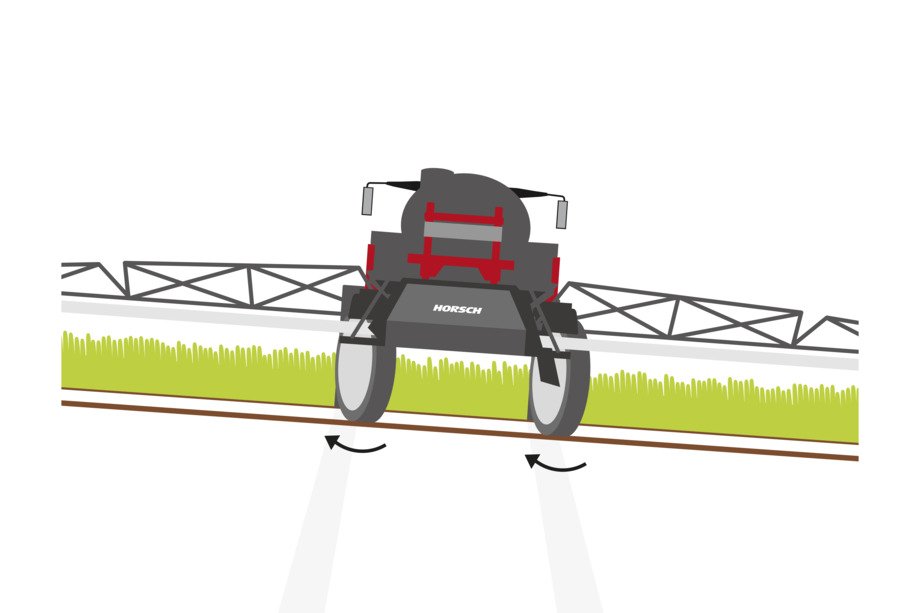

TrackControl TrackControl

- Hydraulic adjustment of the track width in the cab

- Adaption to different crops and row widths

- Track width from 118" to 161"

The hydraulic flange adjustment TrackControl allows for a reliable and comfortable adjustment of the track width of the self-propelled sprayer HORSCH Leeb VL.

The track width can be adjusted infinitely from 118" to 161" to react to any crop and row width. Tramlines can be avoided and stability and driving characteristics improve while spraying.

|

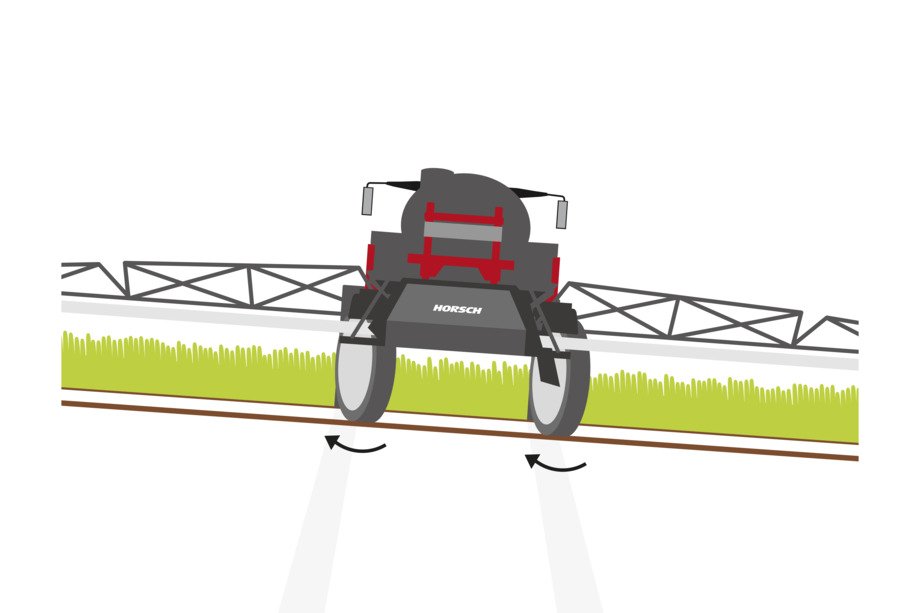

HillControl HillControl

- Track-true self-steering of the rear axle on the slope

- Active slope counter-steering, infinitely adjustable aggressiveness

- Simple operation, stored values are recalled in any direction of travel

- Safer driveability on side slopes under demanding conditions

With the HillControl equipment, the rear axle of the self-propelled HORSCH Leeb plant protection sprayer is controlled separately. This ensures safe maneuverability on slopes even under difficult conditions. The slipping of the machine is actively overridden and the aggressiveness of the steering is continuously adjusted.

Operation is incredibly simple: activate HillControl and, if necessary, adjust the steering slightly to suit the conditions. The system stores the values until the next time the linkage is folded in - in any direction of travel across the entire field.

The active hillside counter-steering system HillControl compensates drift on side slopes and ensures a directionally stable following of the rear axle.

|

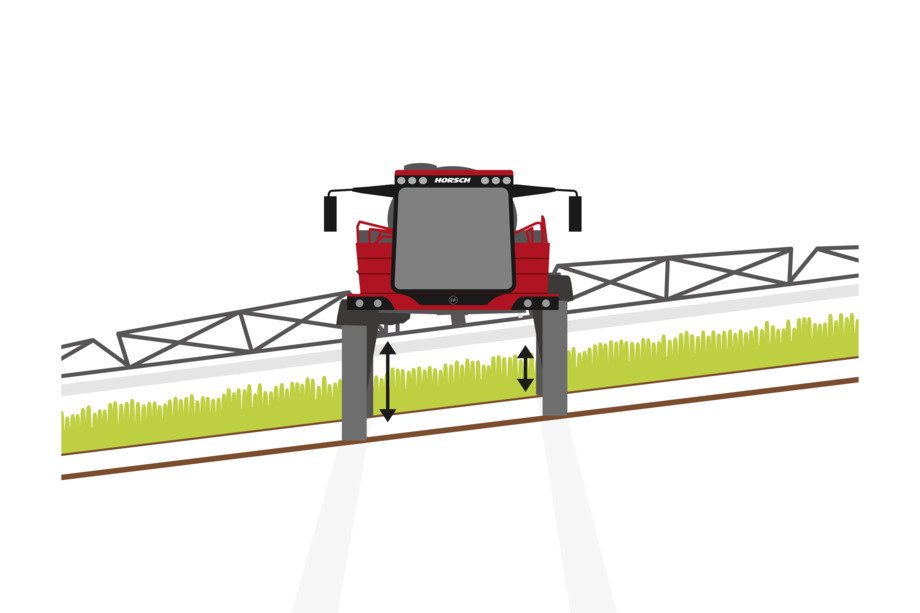

HillControl Pro HillControl Pro

- Active levelling of the vehicle chassis on the side slope

- In combination with ClearanceControl, the vehicle chassis is permanently adjusted to the side slope

- Comfortable workplace in the cab and optimum center of gravity of the machine on the slope

- Only in combination with HillControl: true tracking of the rear axle on the side slope

HillControl Pro additionally regulates the clearance continuously and individually for each side to always keep the chassis in a horizontal position.

|

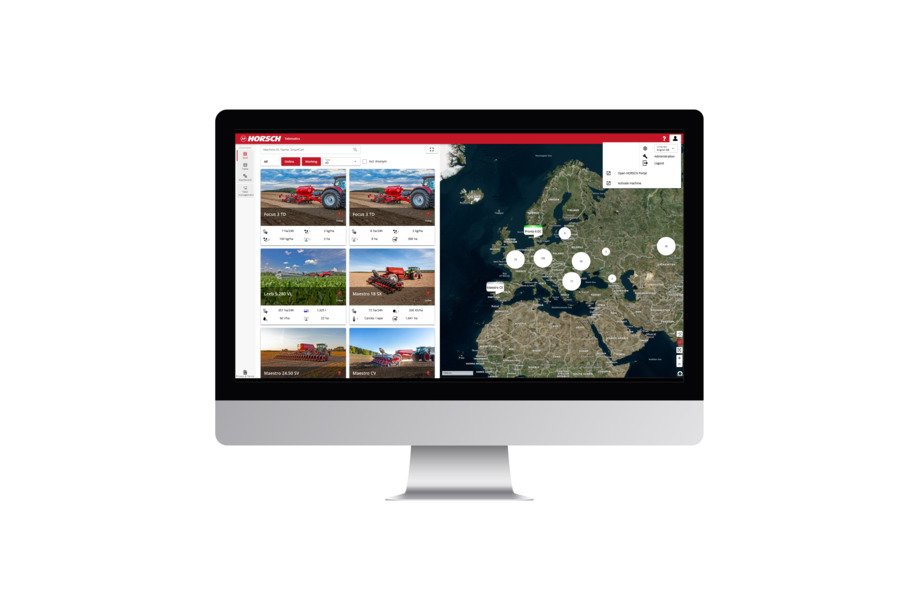

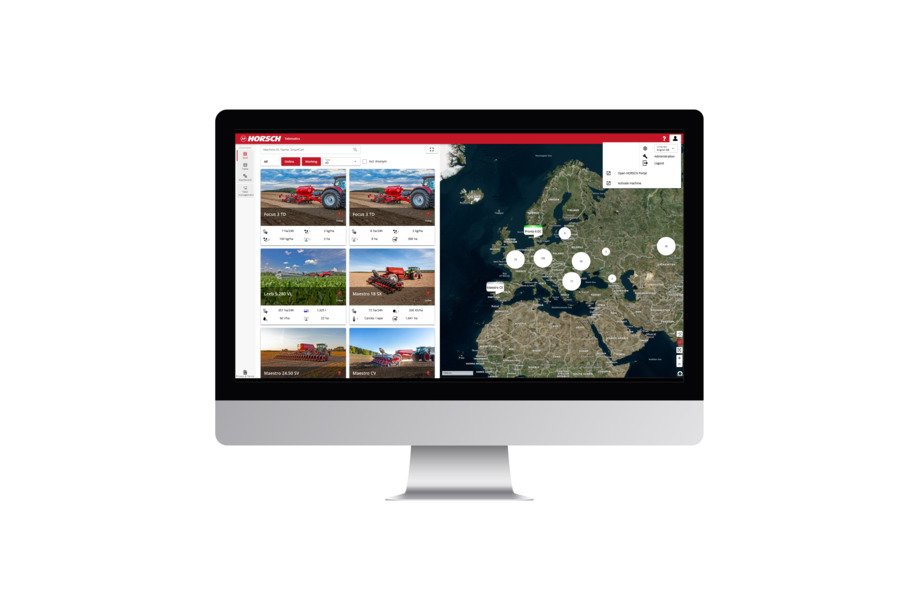

HorschConnect HorschConnect

- Digital solutions exactly where they make sense

- Straightforward out-of-the-box solution with integrated SIM card, WIFI modem and other interfaces

- HorschConnect Telematics to document the performance of the machine

- HorschConnect Telematics for complete transparency of the working quality, e.g the application rate of all components

- Targeted and proactive service due to remote insight in the error messages

- Control of machine functions via smartphone app MobileControl: e.g. calibration of all metering units

Prepare today for tomorrow. Control different machine functions quite easily via the MobileControl app – your smartphone replaces the terminal! In addition, gain complete, transparent insight in all aspects of work performance and working quality with HorschConnect Telematics.

With HorschConnect telemetry solutions can be found in the seeding, planting and plant protection sector – exactly where they make sense

|

3 Year standard warranty 3 Year standard warranty

- All implements that are retailed after 1st January 2024

- For all equipment types including tillage, seeders, planters and sprayers

- For North America

Ask your local HORSCH Dealer for further information on the HORSCH Warranty Policy.

|

Basic

Basic CCS

CCS CCS Pro

CCS Pro Distribution system and induction hopper

Distribution system and induction hopper PowerGear wheel drive

PowerGear wheel drive HighPowerGear wheel drive

HighPowerGear wheel drive Boom variants

Boom variants MotionControl

MotionControl BoomControl Pro

BoomControl Pro BoomControl Pro Plus

BoomControl Pro Plus BoomControl/BoomControl Pro extension

BoomControl/BoomControl Pro extension AutoSelect

AutoSelect AutoSelect Pro

AutoSelect Pro Pneumatic nozzle and section control

Pneumatic nozzle and section control PrecisionSpray

PrecisionSpray Ergonomic operating concept

Ergonomic operating concept Cabin Basic

Cabin Basic Cabin Pro

Cabin Pro TrackControl

TrackControl HillControl

HillControl HillControl Pro

HillControl Pro HorschConnect

HorschConnect 3 Year standard warranty

3 Year standard warranty Terminal technology & steering system

Terminal technology & steering system Induction hopper made of stainless steel

Induction hopper made of stainless steel NightLight

NightLight Hose with hose reel

Hose with hose reel Hydraulically driven high-pressure cleaner

Hydraulically driven high-pressure cleaner PowerFill filling pump

PowerFill filling pump Wheel housings

Wheel housings Central lubrication unit

Central lubrication unit Cabin suspension

Cabin suspension Camera system

Camera system