Search Inventory

Versatile NEMESIS MODELS 235

-

ID # 25864872

- Back ID:25864872

- Get Directions

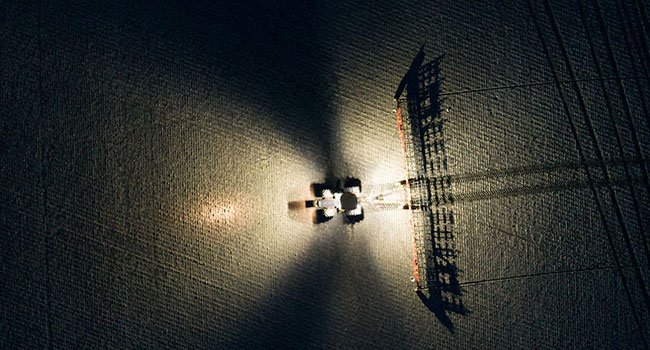

| The Versatile Nemesis is built with productivity in mind. These mid-range tractors are truly versatile and can be used in a wide variety of applications ranging from mowing, baling, material handling and field work. Top-of-the-line features and options include the largest cab in the industry, an advanced hydraulics system and choice of CVT or powershift transmission. The five Nemesis models are the 175, 195, 210, 235 and 255. |

|

|

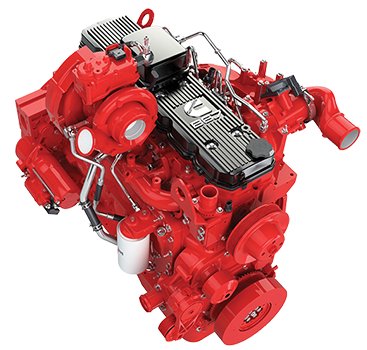

The Nemesis is powered by a reliable Stage V compliant Cummins B6.7 engine that features the latest in diesel technology. The engine is known for maintaining torque for long periods of time and when working through unexpected tough spots in the field. The award-winning Cummins VGT (Variable Geometry Turbo) is proven to be one of the most reliable turbo designs in the industry. The optional reversible engine fan results in improved fuel economy and better airflow across the cooling package, reducing horsepower requirements.

The Nemesis is powered by a reliable Stage V compliant Cummins B6.7 engine that features the latest in diesel technology. The engine is known for maintaining torque for long periods of time and when working through unexpected tough spots in the field. The award-winning Cummins VGT (Variable Geometry Turbo) is proven to be one of the most reliable turbo designs in the industry. The optional reversible engine fan results in improved fuel economy and better airflow across the cooling package, reducing horsepower requirements. |

|

TRANSMISSION

|

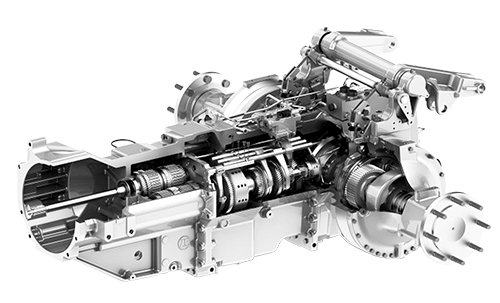

Powershift

Powershift

The ZF powershift transmission balances power and productivity. The auto-shift feature allows for set rpm and ground speeds without constant input from the operator. The Intelligent Range Shift (IRS) quickly reaches optimum working speeds resulting in less operator fatigue by offering full speed matching (30 forward and 15 reverse). The ZF powershift comes standard on the 175, 195 and 210. |

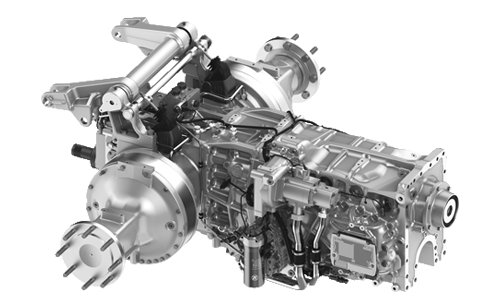

CVT

CVT

Stay in continuous control with a CVT from ZF. The transmission can be easily operated using the command lever or foot throttles. The high-low adaptive speed selections are programmed to meet the needs of various jobs and applications around the farm. The CVT is standard on the 235 and 255, and optional for the 175, 195 and 210. |

| Versatile four-wheel drives are equipped with a standard 53 gpm (201 L/min) pump or an optional 106 gpm (401 L/min) high flow pump hydraulic system. The closed center load sensing hydraulic system provides ample capacity for implements that demand high hydraulic flow by providing pressure and flow on demand. When no hydraulic power is required, the system goes into low-pressure standby to conserve energy, providing more power at the drawbar. |

| Controls - Finger-tip controls manage the hydraulic functions and hydraulic flow can be increased and decreased using the monitor. Hydraulic settings can be displayed on the monitor for quick reference. |

|

Hydraulic Accessories

|

|

Standard Features

|

|

The 275, 295 and 315 front axle come standard with a limited-slip differential that automatically increases traction in various ground conditions. When even more traction is required an optional locking differential is available that delivers full power equally to both wheels. The 335 and 365 front axle come standard with suspended differential locking axle. Efficient speed reduction from the transmission to the ground is achieved using a heavy-duty inboard planetary axle. The inboard planetary axle is driven by a large crown and pinion gear set. The heavy-duty cast iron rear axle housing protects components for years of trouble free operation. |

|

The drawbar is equipped with an auto hitch pin that will automatically drop in place when hitching up implements. When backing up the tractor to attach an implement, the implement hitch will contact the release strap and the pin then drops automatically into place, without the operator having to leave the cab, or without the need of a second operator. |

|

3-Point Hitch

|

|

Rear 3-Point Hitch

The rear 3-point hitch is engineered for quick and simple engagement and can be easily operated using the armrest controls. The rear hitch on the 175, 195 and 210 has a lift capacity of 15,543 lbs (7,050 kg). The rear hitch on the 235 and 255 has a lift capacity of 16,314 lbs (7,400 kg) and optional lift capacity of 19,400 lbs (8,800 kg). |

|

Rear PTO

The rear PTO system features an ECO mode which reduces engine rpm to increase fuel efficiency. The standard and ECO mode selections are conveniently located on the right rear corner. The size of the standard PTO is 540 rpm (1⅜", 6 spline) and 1,000 rpm (1⅜", 21 spline) with a larger 1,000 rpm (1¾", 20 spline) upgrade available. |

|

Front 3-Point Hitch & PTO (optional)

Use a wide range of attachments with the optional front 3-point hitch with PTO. The size of the front PTO is 1,000 rpm (1⅜", 21 spline). The front hitch on all models features a lift capacity of 8,818 lbs (4,000 kg). |

The MFWD can be customized to meet specific working conditions with a range of available lighting packages. The standard lighting package includes two hood mounted headlights, two front and two rear halogen worklights, four roof mounted worklights and one rear mid worklight that is switch controlled. Available lighting options include:

|

|

SERVICE

Versatile tractors are designed with easy serviceability in mind because there are never enough hours in the day. Routine service can extend tractor life, minimize downtime and lower operating costs. |

| Daily Maintenance - Daily and regular maintenance can be completed in a fraction of the time with easily accessible service and sight gauges. The hydraulic and fuel sight gauges are visible from the ground without opening side panels or removing any shields. The gullwing-style side panels open wide to provide excellent service access to all under-hood components. |

| Grille Access - The front grille swings open to provide ground-level service access to the condenser and cooler package. The batteries are located behind the grille at ground level. A shut-off switch is standard for safety, winter storage, and to prevent theft. A steel ballast is mounted under the front of the tractor improving service access, visibility and reducing storage size. |

| Axle Servicing - The Versatile outboard planetary axle system is known for its ease of service. Planetary axle covers can be removed from the tractor without removing the axles or the tires, limiting the time needed for routine maintenance. The gears can be reversed to double the wear life. In addition, daily inspections are easy with a quick visual check of the axle oil level sight gauges. |

| Oil Filters - The oil filters are conveniently placed for easy access and service. |

| Fuel Sight Gauge - A full-length fuel sight gauge gives operators a quick view of the fuel level before entering the tractor. The fuel gauge is protected underneath the entrance ladder. |

| Fueling - Refueling is simple and a crossover tube allows both tanks to be filled quickly. Farmers can work uninterrupted for many hours with large fuel capacities of 300 and 400 U.S. gallons (1,135 and 1,514 L). |

| Access - A right-hand ladder helps with fueling and provides easy access to the engine air cleaner for quick servicing. |

| Air Cleaner Assembly - A dry element air filter is easily accessed and removed when it needs to be replaced. |

Having better information means making better decisions. The Versatile CBX system can be used to monitor equipment history, mapped location, idle time and fuel levels. The CBX system securely and instantly shares relevant equipment information if an issue occurs. This technology makes it possible to fully understand the situation and quickly find an effective solution, resulting in less downtime.

Having better information means making better decisions. The Versatile CBX system can be used to monitor equipment history, mapped location, idle time and fuel levels. The CBX system securely and instantly shares relevant equipment information if an issue occurs. This technology makes it possible to fully understand the situation and quickly find an effective solution, resulting in less downtime.